It all starts with the reception of grain.

The basis of quality flour is the right choice of raw material. Because we have a positive relationship with the Czech countryside, we prefer raw material from Czech growers.

Before each delivery of grain is composed, we carry out a careful input analysis using modern equipment.

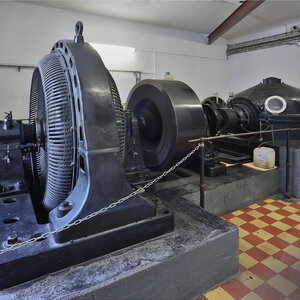

This is followed by cleaning and preparation of the grain.

The most important miller’s motto is: “As you clean, so you grind”. That is why we take great care in preparing the grain before milling. The grain is then moistened and left to rest for 10 hours. Thanks to this preparation, we are able to extract the most valuable parts of the kernel for the highest quality flours. Just before milling, the grain is surface-treated (milled) to remove microbiological contaminants.

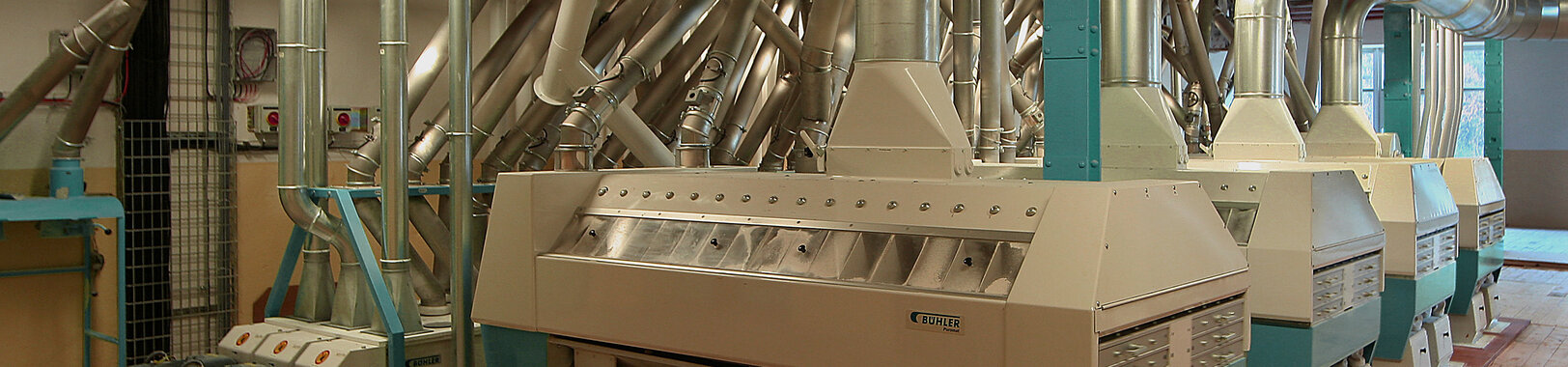

And on to the mill.

The mill is equipped with modern Swiss Bühler machines with a total capacity of 180 tons/24 hours. The grinding method is based on the proven Czech school. The grain is gradually ground so as to extract all the semolina and semolina of the flour kernel while preserving its baking properties to the maximum.

We produce all traditional types of flour and we can make special designs for flours with certain baking properties.

Quality flour also needs to be packaged well. Packaging.

For small consumer packaging we currently have the most modern packaging centre in the Czech Republic from the German renowned manufacturer Fawema with a capacity of 110 bags per minute. We are able to pack flour on classic EUR pallets or atypical DD pallets. We can offer flour in classic group packing of 10 kg or bulk bags.

Wheat mill — solution for feed storage and new packaging and palletisation

Funding

This project is financed from the Rural Development Programme 2014 – 2020 according to the conditions valid for the 10th round of applications — Operation 4.2.1. Objective of the operation — investment in processing operations leading to an increase in the added value of agricultural products.

Brief description

The project focuses on the modernization of the existing feed storage and the construction of a new covered feed dispatching facility, the result of this part of the investment is to increase the hygienic safety during the dispatching of feed (elimination of dust during loading), improve the working environment for the operators and the surrounding area and, last but not least, speed up the loading of bulk feed. The second part of the investment is the construction of a new hall as an extension to the existing mill building and the equipment of this hall with modern packaging and palletizing technology. The construction of the new packaging centre will increase competitiveness in the market for small consumer packaging of flour or other mill products. It will also provide the possibility of expanding the portfolio of products offered to small consumers, the ability of the palletiser to stack individual bags on a pallet, improve the logistics of transporting packaged flour, and reduce the number of claims for torn goods. The relocation of the packing house to the new extension will increase the storage capacity of finished products by at least 250 pallet spaces by expanding the warehouse by the space of the original old packing house.

Video nelze přehrát bez souhlasu s cookies.